Accurate Ultrasonic Distance Measurement Project

Abstract - This paper introduces a different approach to

the measurement of the time-of-flight of ultrasonic signals.

Frequency variation monitoring and recording is used to

determine accurately the arrival time of the ultrasonic signal.

A high speed Digital Signal Processor (D.S.P.) is used for

both: transmission and direct measurement of the frequency

of the incoming signal in every single period and with an

accuracy of about 0.1%. The proposed configuration offers

small size and low cost solution to displacement

measurements with a remarkable performance in terms of

accuracy, range and measurement time.

THE SYSTEM

The configuration of the proposed system is based on the

capabilities of accurate time measurement of modern microcontrollers.

The usual series of microcontrollers can not be

used in this application mainly because of their relatively

low frequency of operation (clock frequency) which affects

the accuracy of time measurement within one single period.

They can not offer the required fast and accurate frequency

measurement. A high performance system may therefore be

built only on a more powerful microcontroller. Larger

systems (personal computer type, etc) are avoided for

practical reasons; the overall measurement system should be

cost-effective and small sized.

More pdf

Ultrasonic Distance Sensor Implemented

with the Microcontroller Project

Linear measurement is a problem that a lot of

applications in the industrial and consumer market

segment have to contend with. Ultrasonic technology is

one of the solutions used by the industry. However, an

optimized balance between cost and features are a must

for almost all target applications. The ultrasonic distance

measurer (UDM) is used mainly when a non-contact

measurer is required. This is the type of solution this

document explains using a simple robot toy

implementation.

Description

The UDM is a demo that shows capability and performance

of the MC9RS08KA2 and the ultrasonic sensor to build a

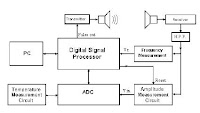

distance measurer. Figure 2 shows the basic building block of

this project.

Ultrasonic Distance Sensor Implemented

with the Microcontroller Project

Linear measurement is a problem that a lot of

applications in the industrial and consumer market

segment have to contend with. Ultrasonic technology is

one of the solutions used by the industry. However, an

optimized balance between cost and features are a must

for almost all target applications. The ultrasonic distance

measurer (UDM) is used mainly when a non-contact

measurer is required. This is the type of solution this

document explains using a simple robot toy

implementation.

Description

The UDM is a demo that shows capability and performance

of the MC9RS08KA2 and the ultrasonic sensor to build a

distance measurer. Figure 2 shows the basic building block of

this project.

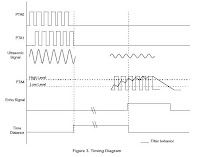

The firmware generates a 40 kHz burst signal. After the 10 cycle

burst is completed, a variable that measures the distance is

activated. This variable measures the time sound takes to rebound

and is used for distance calculation.

The burst signal goes to the ultrasonic transmitter (US Tx) and is

transmitted as ultrasound through the air Figure 2. When the wave

is reflected off an object, this wave is captured by the ultrasonic

receiver (US Rx.) This received signal is amplified because it

attenuates as it travels. Afterwards, the signal goes back to the

microcontroller unit (MCU), filters it and calculates the distance.

A 40 kHz interrupt is generated by the timer in the MCU. To

perform this, the keyboard interrupt (KBI) is enabled and detects

the external signal. Every time the MCU is interrupted the counter

is increased by three. And the variable used as a counter is

decreased by one for the entrances to the modulus timer module

(MTIM) interrupt service routine (ISR). When this variable is bigger

than eight the ECHO signal is activated. The distance variable is then

set to 0. Refer to Figure 3 for timing diagram. For detailed information

about the firmware see Figure 3.

burst is completed, a variable that measures the distance is

activated. This variable measures the time sound takes to rebound

and is used for distance calculation.

The burst signal goes to the ultrasonic transmitter (US Tx) and is

transmitted as ultrasound through the air Figure 2. When the wave

is reflected off an object, this wave is captured by the ultrasonic

receiver (US Rx.) This received signal is amplified because it

attenuates as it travels. Afterwards, the signal goes back to the

microcontroller unit (MCU), filters it and calculates the distance.

A 40 kHz interrupt is generated by the timer in the MCU. To

perform this, the keyboard interrupt (KBI) is enabled and detects

the external signal. Every time the MCU is interrupted the counter

is increased by three. And the variable used as a counter is

decreased by one for the entrances to the modulus timer module

(MTIM) interrupt service routine (ISR). When this variable is bigger

than eight the ECHO signal is activated. The distance variable is then

set to 0. Refer to Figure 3 for timing diagram. For detailed information

about the firmware see Figure 3.