3. Pressure sensor and transducer

3.1 Older ways to pressure measurement with Pressure gauges and switches

Mechanical methods of measuring pressure have been known for centuries. U-tube manometers were among the first pressure indicators. Originally, these tubes were made of glass, and scales were added to them as needed. But manometers are large, cumbersome, and not well suited for integration into automatic control loops. Therefore, manometers are usually found in the laboratory or used as local indicators. Depending on the reference pressure used, they could indicate absolute, gauge, and differential pressure.

3.2 Advancement of Pressure sensors From Mechanical setup to Electronic setup

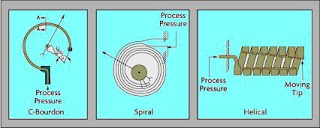

The first pressure gauges used flexible elements as sensors. As pressure changed, the flexible element moved, and this motion was used to rotate a pointer in front of a dial. In these mechanical pressure sensors, a Bourdon tube, a diaphragm, or a bellows element detected the process pressure and caused a corresponding movement.

3.2.1 Transducer Types

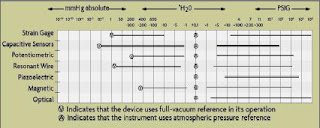

Figure provides an overall orientation to the scientist or engineer who might be faced with the task of selecting a pressure detector from among the many designs available. This table shows the ranges of pressures and vacuums that various sensor types are capable of detecting and the types of internal references (vacuum or atmospheric pressure) used, if any. Because electronic pressure transducers are of greatest utility for industrial and laboratory data acquisition and control applications, the operating principles and pros and cons of each of these is further elaborated in this section.

3.2.1.1 Capacitance

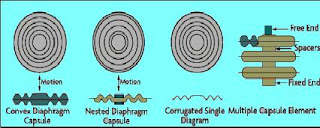

Capacitance pressure transducers were originally developed for use in low vacuum research. This capacitance change results from the movement of a diaphragm element (Figure ). The diaphragm is usually metal or metal-coated quartz and is exposed to the process pressure on one side and to the reference pressure on the other. Depending on the type of pressure, the capacitive transducer can be either an absolute, gauge, or differential pressure transducer.

3.2.1.2 Potentiometric

The potentiometric pressure sensor provides a simple method for obtaining an electronic output from a mechanical pressure gauge. The device consists of a precision potentiometer, whose wiper arm is mechanically linked to a Bourdon or bellows element. The movement of the wiper arm across the potentiometer converts the mechanically detected sensor deflection into a resistance measurement, using a Wheatstone bridge circuit (Figure )

BACK to Content Page

.

Next Page .

Previous Page

Control Systems Projects in Industrial Electronics ,Wireless Pressure Sensors – Digital Pressure Sensor Transmitter,Energy Micro energy friendly ARM Cortex-M3 EFM32 microcontrollers extend an applications battery life , boost pressure sensor,Pressure sensor interfacing with Microcontroller,microcontroller pressure sensor project a pressure sensor detects the pressure,The HSCDANN001BA2A3 is a very accurate absolute pressure sensor from Honeywell, pressure sensor and adc ,8085/8086 Microprcessor and 8051 micro controller pressure sensor to microcontroller this project a barometric pressure sensor

3.1 Older ways to pressure measurement with Pressure gauges and switches

Mechanical methods of measuring pressure have been known for centuries. U-tube manometers were among the first pressure indicators. Originally, these tubes were made of glass, and scales were added to them as needed. But manometers are large, cumbersome, and not well suited for integration into automatic control loops. Therefore, manometers are usually found in the laboratory or used as local indicators. Depending on the reference pressure used, they could indicate absolute, gauge, and differential pressure.

3.2 Advancement of Pressure sensors From Mechanical setup to Electronic setup

The first pressure gauges used flexible elements as sensors. As pressure changed, the flexible element moved, and this motion was used to rotate a pointer in front of a dial. In these mechanical pressure sensors, a Bourdon tube, a diaphragm, or a bellows element detected the process pressure and caused a corresponding movement.

3.2.1 Transducer Types

Figure provides an overall orientation to the scientist or engineer who might be faced with the task of selecting a pressure detector from among the many designs available. This table shows the ranges of pressures and vacuums that various sensor types are capable of detecting and the types of internal references (vacuum or atmospheric pressure) used, if any. Because electronic pressure transducers are of greatest utility for industrial and laboratory data acquisition and control applications, the operating principles and pros and cons of each of these is further elaborated in this section.

3.2.1.1 Capacitance

Capacitance pressure transducers were originally developed for use in low vacuum research. This capacitance change results from the movement of a diaphragm element (Figure ). The diaphragm is usually metal or metal-coated quartz and is exposed to the process pressure on one side and to the reference pressure on the other. Depending on the type of pressure, the capacitive transducer can be either an absolute, gauge, or differential pressure transducer.

3.2.1.2 Potentiometric

The potentiometric pressure sensor provides a simple method for obtaining an electronic output from a mechanical pressure gauge. The device consists of a precision potentiometer, whose wiper arm is mechanically linked to a Bourdon or bellows element. The movement of the wiper arm across the potentiometer converts the mechanically detected sensor deflection into a resistance measurement, using a Wheatstone bridge circuit (Figure )

BACK to Content Page

.

Next Page .

Previous Page

Control Systems Projects in Industrial Electronics ,Wireless Pressure Sensors – Digital Pressure Sensor Transmitter,Energy Micro energy friendly ARM Cortex-M3 EFM32 microcontrollers extend an applications battery life , boost pressure sensor,Pressure sensor interfacing with Microcontroller,microcontroller pressure sensor project a pressure sensor detects the pressure,The HSCDANN001BA2A3 is a very accurate absolute pressure sensor from Honeywell, pressure sensor and adc ,8085/8086 Microprcessor and 8051 micro controller pressure sensor to microcontroller this project a barometric pressure sensor

No comments:

Post a Comment